An Introduction to the cold chain

The cold chain is a system used for keeping and distributing frozen food and fresh food, vaccines and other biologicals in perfect condition. The process follows from the product being taken from its natural environment, for example; a fish straight from the sea. To its end destination.

The idea of a complete cold chain is that this product is kept at the correct temperature, in the correct storage for every stage of its journey with the aim of the product arriving unperished and as fresh as the moment it was sourced or manufactured.

The cold chain and pharmaceuticals

The pharmaceuticals sector is known for using the cold chain as a basic requirement. Vaccines are sensitive to heat or freezing and must, therefore, the kept at a very precise temperature from the moment of manufacture to reaching the patient. All vaccines which temperature-sensitive should be kept between 2° and 8°c in a cold room or refrigerator or between -15° and -25°c in a freezer room.

This means cold boxes are used between each of these sources and refrigerated trucks to ensure the cold chain is not broken.

Spoiled vaccines can be fatal for the recipient.

Explore pharmaceutical packagingThe cold chain and seafood

When seafood is freshly caught, the quality is high. Over time, this quality will naturally deteriorate, with it the goodness, vitamins and minerals will also decay until it becomes unsuitable for consumption. From the quality and regulatory perspective, fresh seafood should be stored at 0°C and for frozen seafood at–18°c or colder through the complete chain.

Even small breaks in the chain and temperature fluctuations of even 1°c can cause loss of quality or spoilage of the product. Often a broken cold chain can mean food wastage as it is not fit for consumption which is a waste of our natural seafood resource and cost of harvesting and transporting the product.

Explore seafood packagingUnmistakable quality

In a complete cold chain, Tri-pack packaging has been proven to outperform any alternative packaging material, including EPS and cardboard. The perfect choice of material, complemented with additional insulation barriers is the ultimate combination for fresh and unspoiled produce every time.

More about CoolSeal Packaging

Why Tri-pack reign superior

All of Tri-pack packaging systems have been tested against competitor products and at differing points within the cold chain. A very clear advantage is shown over other substrates when tested in a complete cold chain.

Tri-Pack’s patented sealed edge technology sets their packaging apart from the alternatives. The sealed edge closes the fluted ends trapping the air inside the polypropylene walls. This acts as a barrier for the outside elements and temperature.

It also reduces the cooling time by 12 hours compared to polystyrene. This barrier is also perfect for the chilled and frozen food sectors as it makes it FSA approved, 100% dirt proof and 100% waterproof.

Featured Product

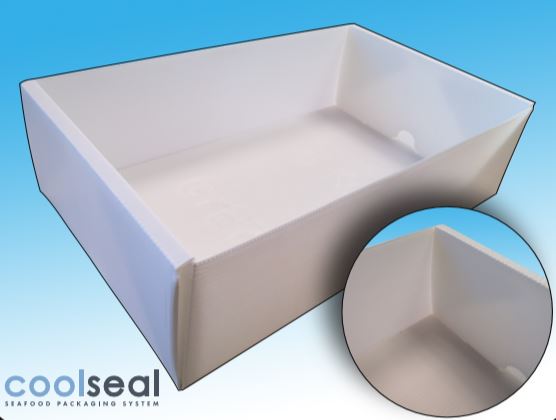

The leakproof box is completely 100% waterproof meaning it is the perfect solution for the cold chain. Packaging fresh fish in ice will store any ice melt or excess water safely in the box without spoiling the contents. The leakproof box also benefits from Tri-packs patented sealed edge technology which adds a barrier to external elements including temperature changes, dirt and dust.

See this packaging

From fishing vessel to plate

Within the seafood sector, produce can go between 12 between channels, from a fishing vessel to collectors, processors all the way to the retailer.

At different stages of this process, the seafood itself goes through many changes including, gutting, bleeding. washing, grading, weighing and sorting.

It is essential that at each stage of both these processes the product is not spoiled. A complete cold chain should be regulated and recorded at every point to ensure these temperature changes are avoided.

It can take 9 days from seafood to reach the retailer from the sea, only in a complete cold chain will this seafood keep the same quality as the moment it was caught.