The problem:

Wealmoor Ltd – a leading global produce grower and packer, got in touch with Tri-pack to look for a packaging solution that offered a lower carbon footprint for their Herbfresh brand, than their current packaging.

A huge consideration for Wealmoor and their operations is the environment, with sustainability a key buying decision. Aligned with this, when speaking to Tri-pack, we knew that our packaging would be a great fit to help them remove carbon from their packaging.

Working with Tri-pack:

At the time of engaging with Tri-pack, Wealmoor used polystyrene packaging for their fresh herb products. As polystyrene is a bulky material, it takes up valuable pallet space – a common problem for many businesses.

Furthermore, Wealmoor stored all polystyrene packaging in a separate warehouse, which involved a team of people who stored and transported the packaging ready for distribution. Offering a flat-pack packaging solution, Tri-pack knew that this was an area where we can bring some huge benefits and impact.

When moving away from a material such as polystyrene, we needed to make sure that the insulation properties – insulation and therefore ensuring product freshness – was at the heart of the new box design too, in addition to the sustainability brief.

Tri-pack stood out to Wealmoor against its competitors early on in the trial stage, due to the multiple benefits we were able to provide.

The outcome:

The main reason why Wealmoor were looking for a packaging alternative was to look at reducing their carbon footprint. How did we achieve this for Wealmoor?

Being able to provide Wealmoor with a flat-packed alternative to polystyrene, meant 70% more storage capacity on a single pallet. This in turn eliminated the need for additional warehouse storage – therefore minimising the CO2 impact of inbound deliveries as well as transport between storage facility and production site.

Switching to a flat-packed, polypropylene box solution means that Wealmoor were provided with a 100% recyclable box option. Not only are our boxes recyclable, but they can be disposed of in everyday domestic recycling streams – without the need for specialist recycling. The ability to recycle each box helps move towards a closed loop economy and ultimately cuts CO2 further.

In addition to meeting the brief for Wealmoor in reducing the carbon footprint of the packaging, there are a number of other benefits that were achieved too…

Cost saving

By being able to reduce the requirement for storage space, and transport between sites, in addition to a carbon saving, there was also a storage cost saving achieved too. Less storage space required, eliminated the need for an additional warehouse – saving Wealmoor unnecessary storage costs.

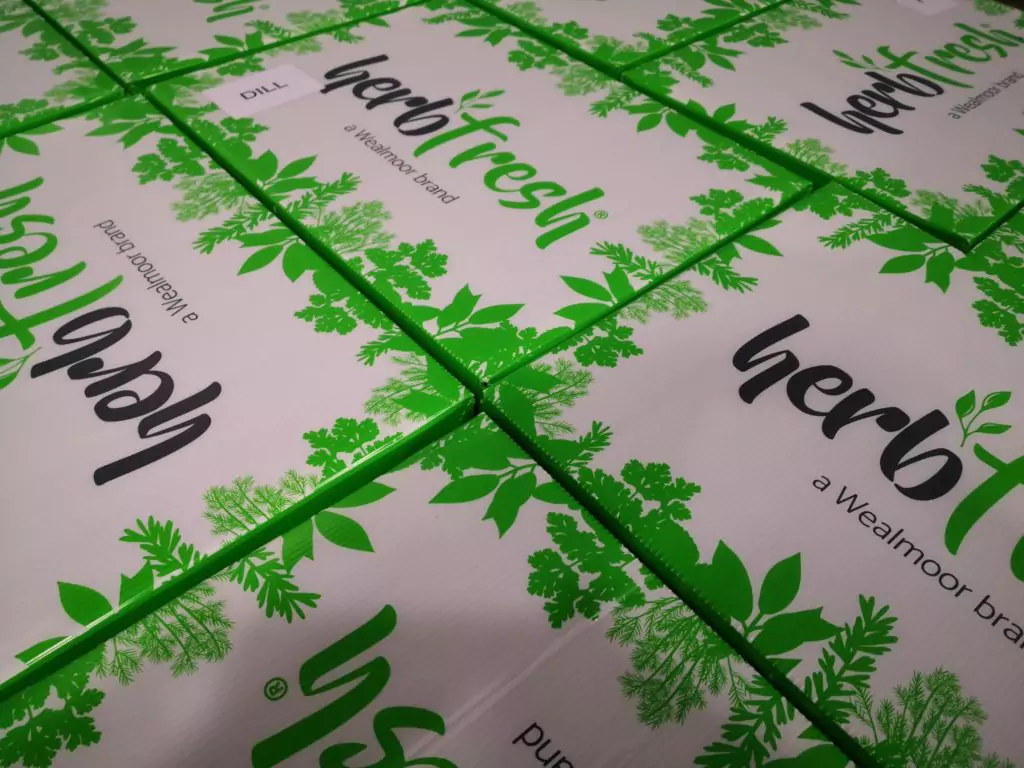

Branding

All of Tri-pack’s packaging can be printed to bespoke requirements. Therefore, with the Herbfresh box for Wealmoor, their branding was incorporated into the box design, which makes it stand out head and shoulders above any polystyrene or cardboard alternatives.

Award winning

Wealmoor were awarded the Innovation Award 2019 for their commitment to plastic reduction, following their move to the Herbfresh box by Tri-pack. Wealmoor stated: “We are excited to be the first to announce a new solution for our herb boxes, moving away from polystyrene to a polypropylene box which has all of the following great benefits: a reduction in carbon footprint, it is 100% recyclable so no need to incinerate or landfill, it is lighter in weight and can be flat packed and reduces the amount of unused transported space, meaning a saving on logistics and storage.”