When transporting fresh fish, processors need to ensure that the packaging used for transporting their processed fish is not only suitable for ensuring high quality of product when moving through the cold chain, but also to bring efficiencies for processors too.

Automated lines are used by fish processors to bring efficiencies to their operations. When choosing fish packaging for transporting processed fish, it should be a key consideration of choosing packaging that can add to these efficiencies.

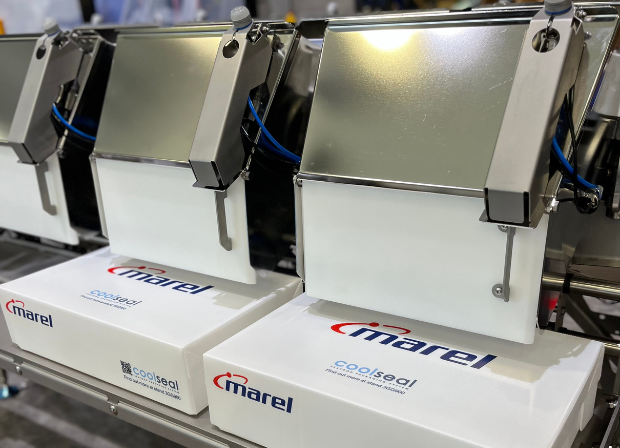

Coolseal fish & seafood packaging is used by both smaller and larger scale fish processors across the UK and Europe, and continues to bring efficiencies for processors that have both manual and automated fish processing lines.

What benefits does Coolseal packaging bring for fish processing automation?

1.Despite it’s lack of sustainability credentials, polystyrene (or EPS) is still the most commonly used material for boxes to transport fish and seafood. With the industry focusing on the insulation properties of EPS, the negatives that come with the material are often overlooked. One such negative being its ability to break – not something that you want to happen with automated processing lines. Being flat packed, and made from a more durable material, Coolseal is often a great choice to ensure smooth operations.

2.With any processing facility comes the need for storage. With fish and seafood moving around quickly in processing facilities, the need to store boxes is therefore of utmost importance. Space can often be at a premium, and as such, moulded polystyrene boxes are not always ideal for processors to store.

Coolseal packaging can help businesses massively with space saving. In fact, when compared to EPS, Coolseal can be stored at much higher quantities per pallet. Therefore in an automated processing environment, you can confidently store more than enough stock to ensure production runs smoothly, and efficiently.

3.Once boxes are filled with processed fresh fish or seafood, there is then the task of distribution. In addition to excellent insulation properties, Coolseal can also help processors reduce their transport costs. The nature of polypropylene means that as well as being a strong material with good insulation properties, you can get much more product per pallet when compared to EPS. Due to the bulky properties of EPS, Coolseal allows you to ship up to 30% more product per pallet than EPS. For processors, especially those with automated lines, Coolseal can therefore help realise a big transport saving.

4.With a wide range of sizes, all being delivered to processors flat packed, depending on the type of fresh fish or seafood you process, we have a box that will be the right size for your automated fish processing operations. With a standard range, as well as bespoke design options we can meet exact box requirements for automated processing.

If you have any questions about your automated processing lines and seafood packaging, then don’t hesitate to speak to us today.