The circular economy is an economic system of closed loops in which raw materials, components and products lose little or no value.

In order for the circular economy to be successful, renewable energy sources must be at the core of the manufacturing process. This indicates that from beginning to end of the manufacturing cycle, from raw material, back to raw material, there is very minimal wastage. The circular economy is a process which has protecting the environment at its essence. The primary goal is to have a positive impact on the environment, not deplete valuable resources. Reduction of resource and waste is also a vital aspect, being able to continuously reuse a simple resource or raw material, reduces greenhouse gases and continuous harvesting or manufacturing of said material is not required.

Circular economy benefits to business

As a business, adopting a circular economy process can reap financial reward. Not only does the cost of raw material deplete dramatically but so does the cost of manufacturing, along with many energy-saving implications. Embracing this process can also offer significant competitive advantage for a business. In an eco-conscious environment, more consumers are investigating how ‘green’ and ‘efficient’ companies claim to be in a bid to protect planet earth. Those businesses who can represent a clear closed-loop circular economy could surpass others.

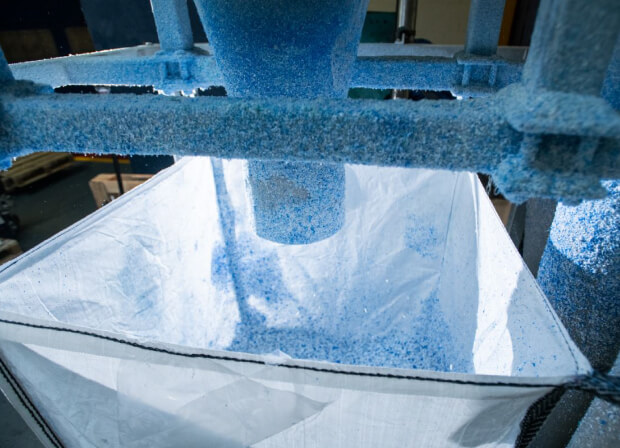

The Circular Economy and Tri-pack

Tri-pack aspires to be the first in their field that boasts a complete circular economy product. Currently, all product kept within their business, including any off-cuts or otherwise distinguished ‘waste’ material is produced back into the original raw material. By 2023, Tri-pack aim to collect back 100% of their packaging from distributors to recycle the product back into the complete raw material. This will close the final loop in their circular economy. For more information on Tri-pack’s sustainability mission and goals contact them today.