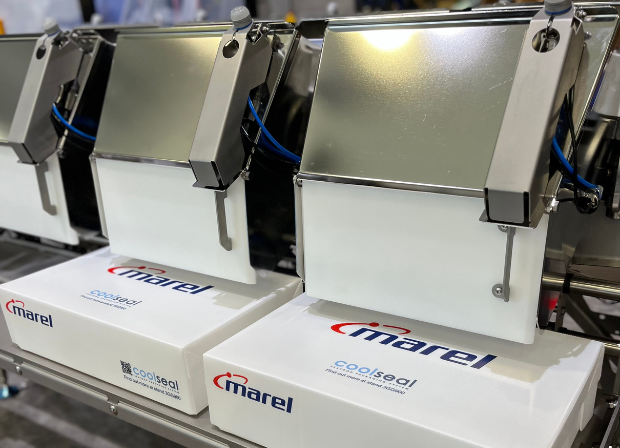

Coolseal boxes are recyclable, insulating, strong, well priced and loved by our customers. Why choose anything else?

Scotprime Seafoods

We feel better knowing all our packaging is not only strong and robust but 100% recyclable by any waste company.

Morrisons

At Coquet Island we like to stand out for all the right reasons. Coolseal boxes allow us to offer our customers a more environmentally friendly alternative to traditional polystyrene packaging. The flexibility of box colour, high-quality print and bespoke sizes is a valuable service right at our fingertips.

Coquet Island Seafood

We have been using Coolseal boxes for a number of years now. We want to be seen as a leading processor, and Tri-pack's boxes allow us to stay ahead of the game, especially with regards to the environment. Because Coolseal is 100% recyclable, it ticks all the boxes.

Nolan Seafoods

At Skagerak Salmon, we strive to deliver the best quality to our customers and Coolseal packaging helps us achieve this. Its recyclability and durability qualities are in high demand and we are proud to supply our seafood in them.

Skagerak Salmon A/S

Here at Glenmar Shellfish we find the Coolseal box perfect for use with our prawns. It provides an excellent presentation and protects the product inside.

Glenmar Shellfish

Packaging products

Information

About

Languages

Tri-pack Packaging Systems Ltd, Estate Road No. 1, Grimsby, N. E. Lincolnshire, DN31 2TB - Registration No.01146130

Copyright © 2025 Tri-pack Packaging Systems Ltd. Website by S4