What we do

We manufacture bulk packaging for business across many sectors, including produce and pharmaceuticals. We use unique tooling methods to create business packaging which reduces pressure on your supply chain. Our packaging is designed to protect your valuable stock, acting as secondary or tertiary packaging, this strong and durable solution protects your products during the transportation stages.

All our packaging is manufactured using polypropylene which is reusable and 100% recyclable, reducing your carbon footprint and supply chain costs.

Our packaging is proven to be one of the most eco friendly packaging solutions available on the mass market.

Explore our clientsWho we work with

We work with large businesses looking to reduce their storage and transport costs.

Providing unique packaging solutions tailored at large orders, we help to reduce your carbon footprint, distribution costs and provide you with an eco-friendly packaging alternative.

With over forty years of experience in manufacturing robust and reliable packaging solutions. We are always at the forefront of innovation; constantly pushing the boundaries and traditional thinking around packaging.

With the simple aim to create advanced and ground-breaking products and processes.

Speak to a consultantMade Great in Grimsby and trusted around the world

Now exporting world-class packaging globally, meeting any requirement from multi printed small 1.5 kilo packs right up to 500-kilo bulk packs, there is no job too big or too small for this packaging giant.

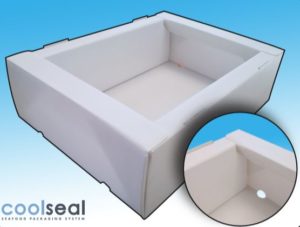

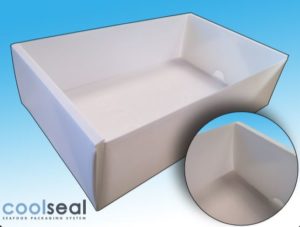

Tri-Pack has the most comprehensive range of polypropylene converting techniques available within the UK making them a market leader. They are the only worldwide provider to use patented unique sealed edging on their packaging, making it solid, waterproof, dust and dirt proof.

Order a free sample...Our Industries

We supply sustainable packaging for a sustainable world

Tri-Pack has over forty years of experience in manufacturing robust and reliable packaging solutions. Always at the forefront of innovation; Tri-Pack is constantly pushing the boundaries and traditional thinking around packaging.

Your packaging, your way

Here to maximize your brand exposure

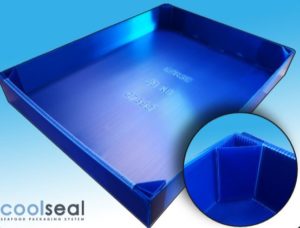

While our regular packaging is white and unbranded, there is always the option to add a logo with our of your choice, we can digitally print and colour match any branding to ensure your packaging is unique to you. This will allow you to stand out from competitors or impress on a shop floor.

Tri-Pack boasts a huge portfolio of global clients including, Lloyds Health Care, Marshalls, Seddon, Morrisons, UKMail and Youngs Seafood.

Get branded packaging today...Our mission

Our mission is to promote the benefits of plastic and to overcome the barriers and negativity built up around it.

We are constantly pushing the boundaries to create products that are diverse and innovative, staying ahead of the competition at all times.

Check out our solutions...

The Right Decision

Here to provide your business environmental positives

Housing our own bespoke machinery, Tri-Pack are able to accommodate any packaging need. Packaging is created bespoke to every client and can be modified with the use of thermal die-cutting, and industry-leading print quality.

We also stock a large number of packaging solutions for quick call off. The high speed glueing techniques and both sonic and hot air welding means your order is processed through the warehouse with both precision and speed; your order is always on time and perfectly formed.

Start your journey to a greener future...Our Distributors

Worldwide shipping at your fingertips.

We are the only worldwide provider to use unique sealed edging on their packaging, making it solid, waterproof, dust and dirt proof.

Discover more about our distributors